“1 Ordering anything from … for any other location of the world – Generally will cause you financial. compliance, & time frame issues.

2 Local Suppliers / Engineers / Clients – generally do not understand International Standards, Laws, Specifications, Other countries requirements. all others should be done with externals Consultants

3 Suggestion – Use Expert Consultants / SME’s (Subject Matter Experts). Suppliers, Clients, EPCs are generally not experts.

4 Accessibility of Equipment for Inspections – Poor access to Lights, slows all processes down. Have Scaffold or EWP available

5 Manpower was too low – Decision was made before Inspection that Technicians were not needed. It was assumed installation was 100% complete

6 Inspector’s findings 100% no issues – Their ‘expertise’ is under-performing

7 Technicians were not trained on this specific Make / Model of Glands

8 Technicians not trained on Barrier Glands

9 Technicians not given specific tools for Glanding

10 Parts and Materials for project were not organized

11 Receiving Inspection by an Ex Competent Person did not happen for Equipment / Parts / Materials

12 Manufacturers sent wrong equipment – Buyer did not find this issue

1 Temperature Elements – ATEX, not IECEx

2 Lights – HazLoc (American Only), not IECEx

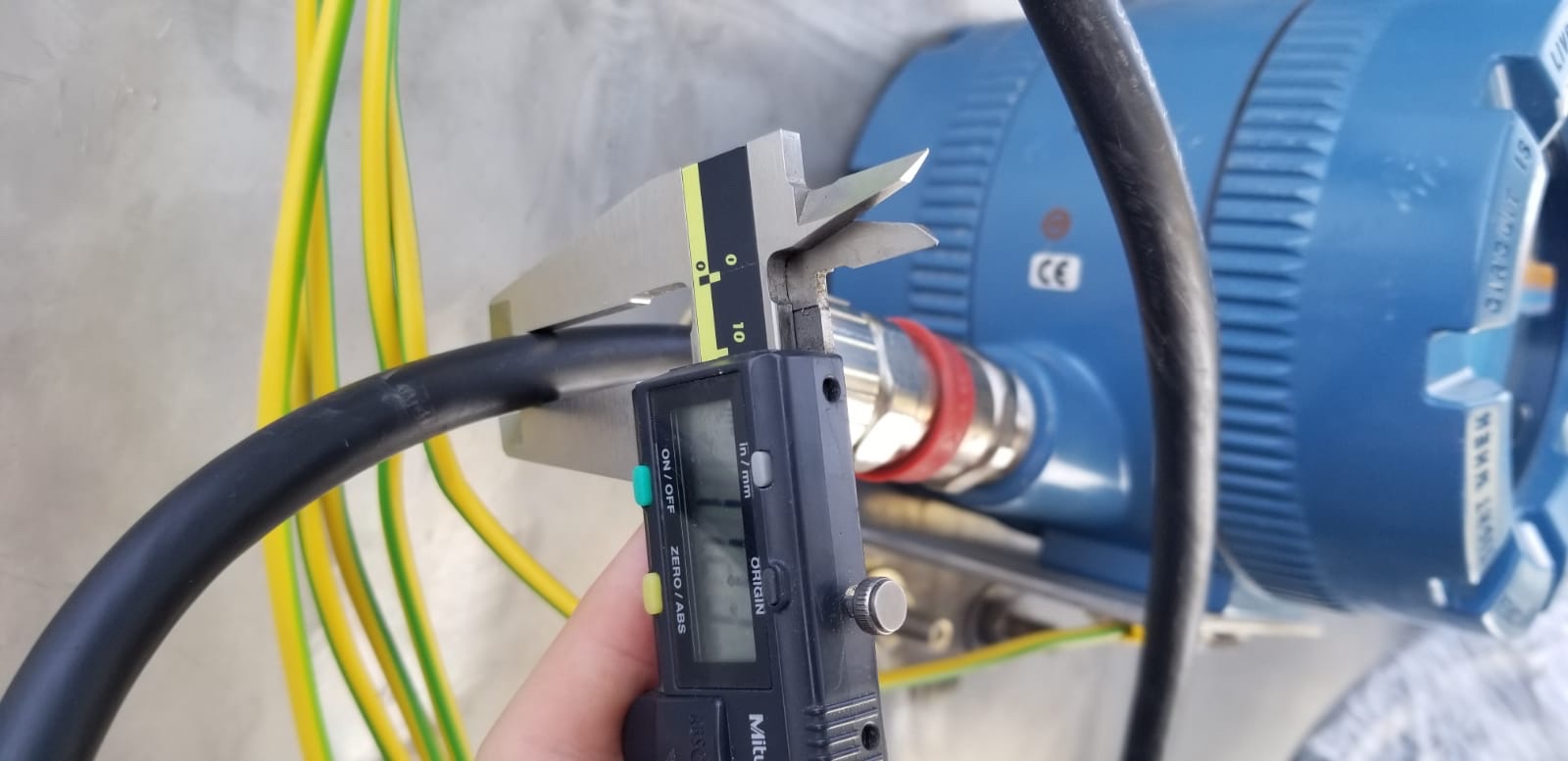

13 Cable Manufacturer – Cable did not match details of their Datasheets

– Cables were 10.8mm overall Diameter – Datasheet said 12.9mm

– Glands ordered were for 12.5mm to 20mm

– All Glands had to be replaced – Glands at Junction Boxes will be an issue

14 Suggestion – Never order equipment that is close to their design limits

15 Received Incorrect equipment

16 Initial inspection, Testing, Preservation of equipment not done by client

– Bench Testing (Megger, Point-to-Point, Calibration)

– Documentation that came with equipment was not provided for review

– Documentation for Receiving of Equipment not provided

17 Documentation – All documentation not provided for review before site visit

– Equipment to be procured / ordered

– Complete list of ALL Cables

– List of all Individual Equipment, Parts, and Materials

– ITR’s – Inspection Test Reports

– Cable Schedules

18 Documentation – All documentation not provided for review during site visit

– Asked multiple times for documentation to be ready, organized, in Binder

19 Incorrect equipment ordered (ATEX, instead of IECEx) – IECEx was mentioned many times, or ATEX would result in a CAD, which costs more money

20 Belief of Clients approvals, instead of Consultants

21 documentation was disorganized / inefficient to find

22 Technical Queries / Requests for Information were not correctly budgeted.

23 Technical Queries / Requests for Information – Were requested in over +50 emails, Conference Videos, Phone Calls

24 Technical Queries / Requests for Information – Were not budgeted

25 Technical Queries / Requests for Information – Were never requested via official documentation

26 Accessibility of Equipment – Maintenance of equipment was not considered

27 Preservation was not well planned for the installation

– No Silicon Grease (DC-4, Molykote) applied to all covers, threads, flamepaths

– Anti-Condensation Packs were not installed

– Cables were poorly secured, where they would swing with the movement of the ship and waves”

This report above – slightly modified from original – I found to be very interesting. It could meet many of Ex projects worldwide. We shall learn from it, and use it as per our own.

Keep up good work!

Arpad