Fixed gas detection systems have been used for many years to perform safety instrumented functions. Like any instrumented system, a fixed gas detection system commonly comprises of a single or multiple gas detector input(s), a control unit and a single or multiple final element(s) or output(s). Additional peripheral equipment may be incorporated into a fixed gas detection system e.g. a gas sampling system or a gas conditioning system. If a fixed gas detection system, including any relevant peripheral equipment is to be effectively used for safety instrumented functions, it is essential that the total system achieves certain minimum standards and performance levels.

It is important to understand that the number of sensing points and their appropriate location, their redundancy, the management of regular maintenance, specifically response checking or calibration, and other gas detection specific features (such as design of gas sampling systems) are all likely to have a far greater effect on the integrity of the overall Safety Instrumented System (SIS) than the required Safety Integrity Level (SIL) or SIL-capability of any of the individual functional units. This, however, does not exclude the requirement for each Safety Instrumented Function (SIF) to have a stand-alone functional integrity.

It is important to understand and categorise the application of the fixed gas detection system. The three main applications are:

• as a prevention system – the total system or an individual instrumented control loop has a safety function and safety integrity clearly defined.

• as a mitigation system – the total system or an individual instrumented control loop has a safety function and safety integrity clearly defined.

• as an additional safe guarding system – this covers those fixed gas detection systems or individual instrumented control loops which operate in parallel (secondary) to an instrumented safety system, where the demand on the fixed gas detection system or individual instrumented control loop is only when the primary instrumented safety system fails or another layer of protection fails.

Under no circumstances should the use of an additional safeguarding gas detection system contribute to the Hardware Fault Tolerance (HFT) declaration for the instrumented safety system.

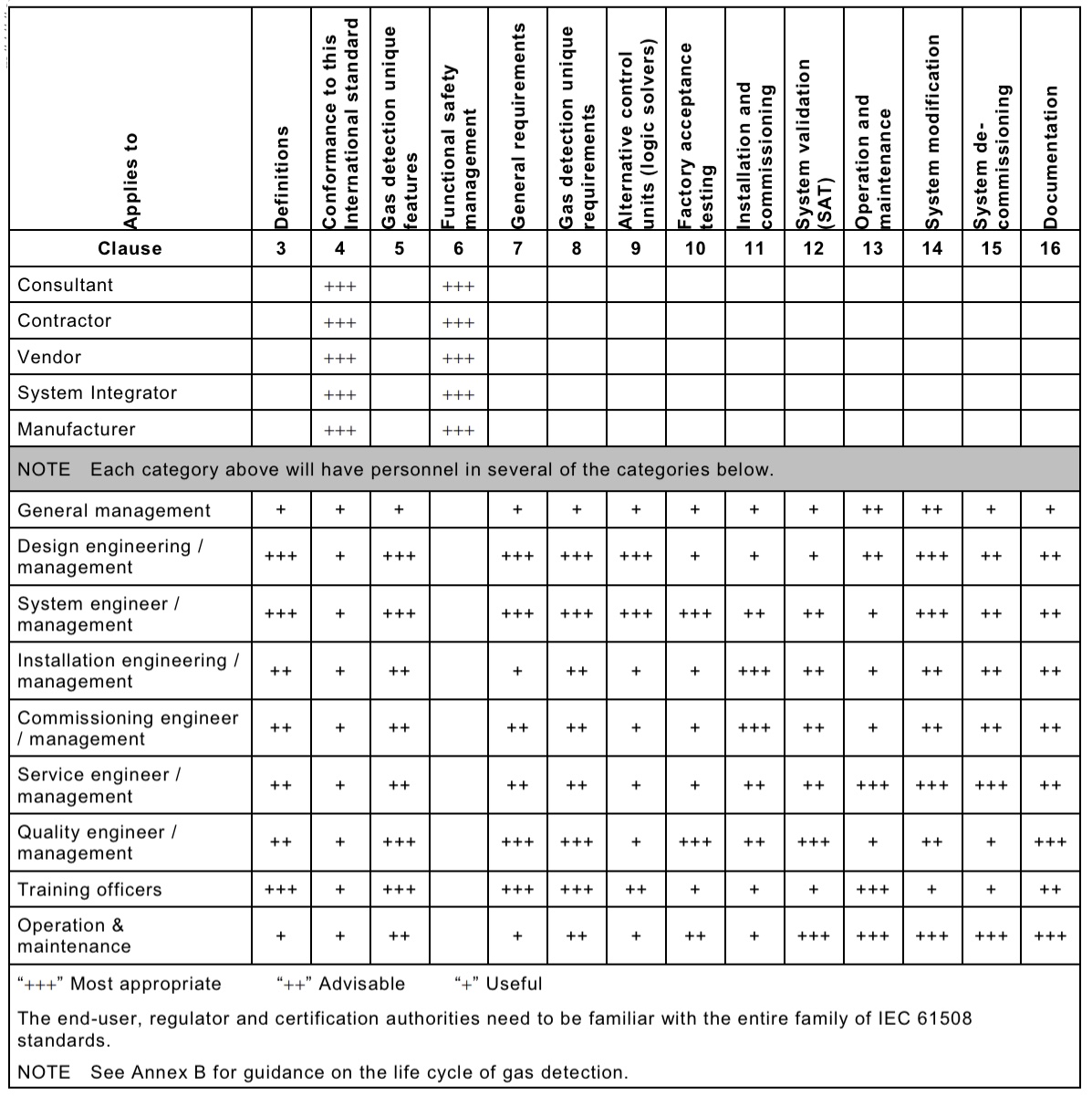

Typical Job Descriptions and Most Relevant Clauses

Source: iec 60079-29-3 // Gas detectors – Guidance on functional safety of fixed gas detection systems

Note: where life in danger normal Ex gas detectors still ok? Pls always refer to this section of the relevant standard before coming to decision.

Keep up the good work.