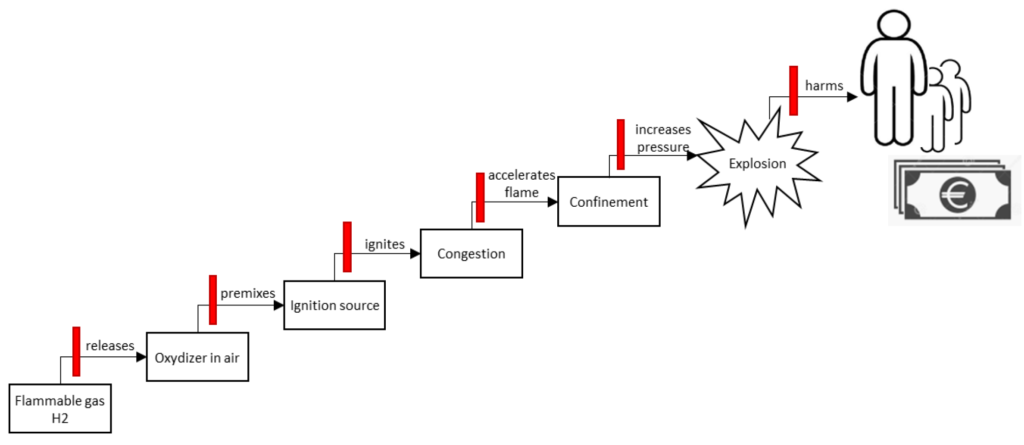

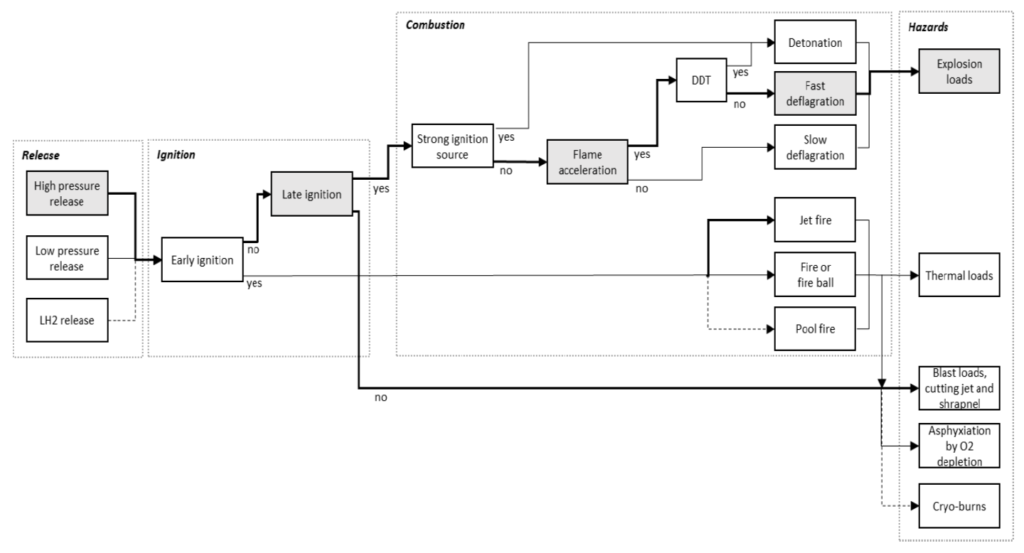

Any hydrogen accident is initiated by a release of hydrogen from a container or pipe which are typically operated at pressures above atmospheric pressure. Sub-atmospheric operation pressures have to be avoided to exclude air ingression. The potential consequences of a hydrogen release are detailed in the event tree shown below.

Ignition and flame acceleration are safety critical as they decide how critical the consequences might be. The vertical upward direction in the figure implies escalation. So, the hazards associated with a “no ignition” accident (e.g. oxygen depletion) are considered less critical than those associated with a delayed ignition and fast combustion regimes, which imply far reaching explosive loads. The most likely escalating sequence observed in the majority of severe accidents, which are in fact gas explosion events, are marked with grey boxes here.

It should be noted that even if the escalation may be stopped successfully at an early stage, certain hazards still will exist. A small unignited release or a jet fire, for instance, won’t generate explosion loads, but will imply considerable physical hazards or thermal loads. The burst of a pressurised pipe or vessel will lead to serious blast loads even without a chemical reaction.

| Explosion Protection Tier |

| Limit hydrogen inventories, especially indoors, to what is strictly necessary. |

| Avoid or limit formation of flammable mixture, by applying appropriate ventilation systems, for instance. |

| Carry out ATEX zoning analysis. |

| Combine hydrogen leak or fire detection and countermeasures. |

| Avoid ignition sources using proper materials or installations in the different ATEX zones, remove electrical systems or provide electrical grounding, etc. |

| Avoid congestion, reduce turbulence promoting flow obstacles (volumetric blockage ratio) in respective ATEX zones. |

| Avoid confinement. Place storage in the free, or use large openings which are also supporting natural ventilation. |

| Provide efficient passive barriers in case of active barriers deactivation by whatever reason. |

| Train and educate staff in hydrogen safety. |

| Report near misses, incidents and accidents to suitable databases and include lessons learned in your safety plan |

THE SAFETY PLAN

A safety plan addresses potential threats and impacts to people, to property and to the natural and built environment as well as the corresponding prevention, mitigation and protection measures. As an integral part of any project, hydrogen installation, and fuel cell system, a safety plan should reflect sound and thoughtful consideration for the identification and analysis of safety vulnerabilities, elimination or control of hazards, and mitigation measures to keep the risk at acceptable level. Appropriate communication is equally important and should be described in the safety plan, including how the plan will be monitored and results of the activities reported as required. A special challenge for an appropriate communication exists in projects, where work typically is conducted by multiple organisations.

Safety plans should be “living documents” that recognise the type of work being conducted, the factors of human error, the nature of equipment life, and consider the inevitable changes that occur in project development and execution.

A safety plan should be prepared using a graded approach based on level of hazards, associated risks and complexity. The plan should cover all work being conducted, including experimental/operational activities, with emphasis on the aspects involving hydrogen safety knowledge, hazardous materials, pressure equipment, hydrogen system peculiarities, etc. There may be cases when a preliminary safety plan is developed during the project application phase as requested by a call. In these cases, elements such as hazards, and associated risk analysis, prevention and mitigation techniques should be covered more generally with a focus on what hazards and risk analysis activities will be completed during the initial design phase after the project is awarded.

The elements of a good safety plan are summarized as follows, though this should not be considered as an exhaustive and mandatory list of safety considerations for all projects:

- Description of Work

- Project Safety Planning

a. Policies and available experience

b. Safety reviews

c. Mitigation plan

d. Procedures

i. Operating steps

ii. Sample handling and transport

e. Equipment and mechanical Integrity

f. Project safety documentation - Operations Management

a. Personnel training

b. Safety review procedures

c. Safety events and lessons learned

d. Emergency response

e. Self-audits

f. Management of change procedures

10 - Additional Documentation and Reporting

a. Flow diagram showing equipment (e.g. PID) including functional description of each component

b. Preliminary layout

c. Extended discussion of RCS and in a case of detailed performance analysis to address the question, if regulations or standards allow for alternatives for simplified correlations or requirements, like tabular safety distance rules, etc.

d. Other Comments or Concerns

e. Details of safety planning, its monitoring and update

Even above no word about non.electrical explosion protection, which shall be a crucial part of explosion protection of TODAY.

Keep up good work!